The transmission of the Utility Task Vehicle (UTV) changes the speed of the wheels and the engine. A range of gears, from low to high gear, is used to make the engine’s torque effective as driving conditions change. You can change the gear automatically or manually. However, nowadays, most UTVs use automatic transmission, which is popularly known as continuously variable transmission (CVT).

Table of Contents

What Makes a CVT Clutch?

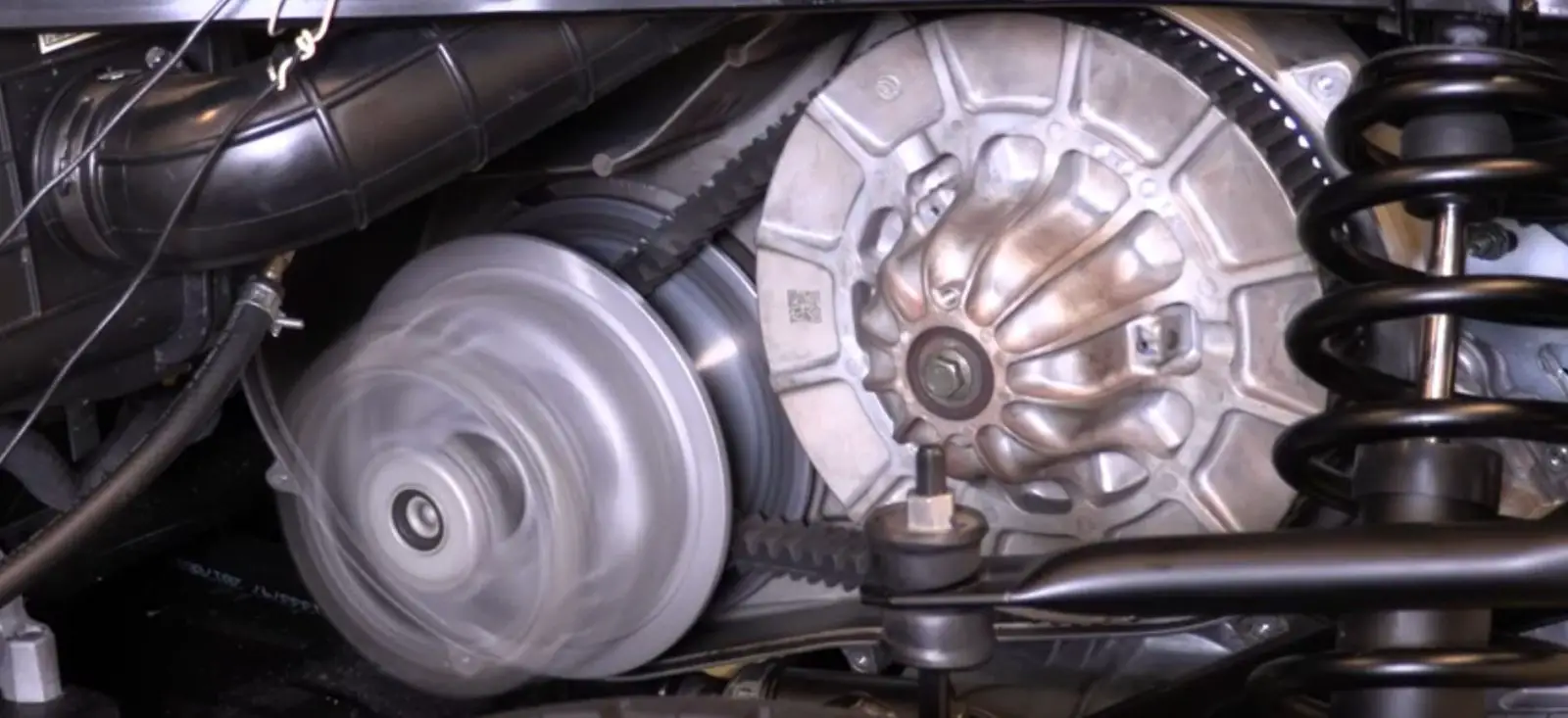

The CVT transmission is unlike traditional automatic transmissions that would be used on vehicles that were too heavy. CVT transmissions don’t come with any gears. Instead, they operate on a pulley system designed to allow variability between the lowest and highest gear with no shifts or steps.

The CVT transmission uses the variable-diameter pulleys as its key. Each pulley comes with two cones facing each other. There also features a belt drive in between the two cones and the groove. When the two cones stretch far apart, the radius of the belt loop that goes around the pulleys becomes smaller, and the belt rides get inside the groove. The opposite happens when the cones are closer to each other.

The crankshaft of the engine is connected to one of the pulleys, which is known as the drive pulley. The other pulley is known as the output or driven pulley. It is turned by a pulley that is connected to the crankshaft. The driven pulley uses the axles to transfer energy onto differentials and to the transfer case and out to the wheels. Everything works great until the UTV is modified. The clutch can slip more and work harder the soon you add more power to the UTV or make changes to aggressive or larger tires. Belt slippage can create excess heat that can destroy CVT belts. Anything that can slow the flow of air over the belt can increase wear and tear. However, the airflow can help cool the belt.

While it is normal for the CVT belt to slip, limiting the slip can reduce heating. Adding weight or making a significant change to your vehicle without changing the way the clutch works can contribute to slipping. And so do extra air filters, pipes, other performance works, and oversize tires. Driving in the sand dunes or in the mud with added stress on the engine can also increase belt slip.

The ability of the CVT system to backshift helps ride the engine while maintaining its powerband. When the engine is on and off the throttle, the backshift responds to this through the crisp throttle. Of course, every driver would want their engine to snap right up in its powerband as the vehicle hit the throttle and blasts through a turn. That will enable the vehicle to pull hard instantly. A lag in throttle response characterizes poor backshifting.

A clutch on a UTV can’t be set up to handle all driving conditions, horsepower, and variations in vehicle weight. However, the clutch can be adjusted with different weights and springs to work for any condition. Clutch kits comprise of weights, springs, and possibly belts that calibrate the clutch.

Perks To Find from a Clutch Kit

- Enhance throttle response and backshifting

- Responsible for improved low and mid-range acceleration

- Efficient transfer of UTV power from the engine down to the wheels

- A minimal belt slippage and reduced clutch heat

Parts of a CVT Clutch

Weights

The role of the weights in a CVT clutch system is to control peak rpm. The weights also determine how quickly the clutch shifts. Lighter weights amount to more rpm while heavier ones equal to less rpm. That means the clutch of a vehicle with a peak power of 6500 rpm should be tuned to hold power during full throttle. Using a little heavier weight can make the clutch shift faster. That’s good news, given that the faster the clutch shifts, the faster the rate of acceleration.

The Primary Spring

Springs are coded with color to make it easier to identify their rating. The color in most springs is given at a rate that is measured in pounds per square inch. The red spring normally doesn’t have a rating, but the black and gold do. The PSI rating indicates how the spring would measure when compressed down. However, note that not all spring manufacturers use the same measuring parameters. So, you might need to find out how a specific manufacturer measures their spring rating before buying springs for your UVT.

The Secondary Spring

The secondary spring comes with features that are almost similar to the primary spring. It is measured in PSI, and it is color-coded. However, it works a little differently from the primary spring. Unlike the primary spring, the secondary spring doesn’t come with weights. Instead, it is designed to put pressure on the clutch to prevent it from opening. It also helps grip the belt. The stiffer the secondary spring, the more pressure will be applied to the belt for the clutch to open. A too steep helix angle and a too soft secondary spring may cause the belt to slip. Slippages can cause more wear and heat on the clutch and the belt. Make an effort to address excessive heat as it can cause the engine to break down.

The Helix

The helix provides resistance to the shift so that the clutch can apply pressure to the belt. The angle of the helix is measured in degrees and can come with multiple angles to create different loads at different parts of the clutch. A typical helix can come with numbers like 50-42.44, with the last number representing the physical cut length or duration of the first angle. The first number represents the two angles that the helix has. Helixes can have less or more aggressive angles to adjust the pressure and load on the belt. The steeper the angle, the more aggressive and fast the clutch can shift. Using a less stiff spring and getting overly aggressive with angles can cause the sprint not to hold enough pressure on the belt. That is likely to cause slippage.

How To Determine the Type of Clutch You Need?

The type of clutch you need depends on your driving style, tire size, and power modes. Your UTV requires a low-end torque to turn its large wheels through the thick mud. Fitting your vehicle with the wrong clutch can cause the engine to rev up. You don’t want to be stuck in the mud so that the belt and clutch don’t overheat. A more top-end power might be suitable for dune driving. So, a clutch with paddles that can turn at high speed works better for dune driving. Using the wrong clutch while dune driving can cause your speed to slow down, especially when climbing a big dune. The wheel will eventually stop moving and get stuck. For trail riding, look for a clutch that has an excellent throttle response. After all, you want a clutch that can punch the throttle while you are exiting a sharp corner.

Tools Needed for the Maintenance of a CVT Clutch

Most of the tools used on the CVT clutches are the basic hand tools used in garages such as ratchets, socket, wrenches, screwdriver, and pliers. However, some specialty tools might be needed during performance maintenance and changing spare parts. A CVT clutch is removed from the engine using a clutch puller, which looks like an oversized bolt. The clutch puller threads into the clutch until it gets on the crankshaft, where it pops the clutch off and forces it backward toward the crankshaft. It might make a loud bang when it loosens from the shaft. The clutch puller is the only tool required to remove a clutch attached to the motor for cleaning and servicing.

The clutch presser is the other useful tool that mechanics use to remove the secondary spring from the UTV clutch. It comprises of a small frame, where the clutch fits into. It has a handle that sites over the surface of the clutch. Mechanics can pull the handle down to put pressure on the spring and the roller assembly to make it easier to remove the snap that holds onto the clutch. The handle ensures that the spring doesn’t hit the user or pop out.

How Maintenance of a CVT Clutch Prevents Poor Performance

Cleaning and inspecting a CVT system can enhance the performance of a vehicle. It is advisable to remove the clutch from the unit often for cleaning and dissembling. Oil-based cleaners and solvents should never be used for cleaning the clutch. Chemicals are likely to absorb into the aluminum sheaves pores and cause the belt to slip. Instead, use a soft brush and soapy water to clean all parts and surfaces of the clutch. Then rinse the clutch well and inspect each part for cracks, rub marks, and wear. A cracked or scratched part may not be usable, so you might need to replace it. No matter how small a crack is, a cracked clutch is bound to break down.